描述

Stepper Motor Controller + Builtin Driver with reverse connection protection

Key benefits

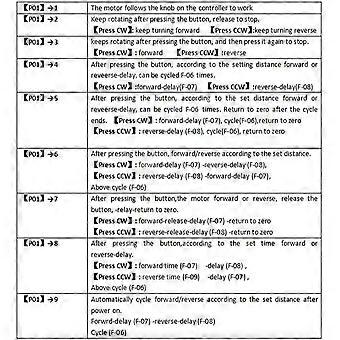

Flexible operation: supports multiple control modes including auto, manual, setting, and serial port control, enabling unsupervised run, manual adjustments, or remote integration.

Wide motor compatibility: can control any twophase stepper motor with 4, 5, 6, or 8 wires, maximizing compatibility with existing motors.

Driver compatibility: capable of driving drivers with similar interfaces, simplifying system design and upgrades.

Smooth motion and reliable timing: includes acceleration and deceleration control to reduce missed steps and mechanical stress, improving positioning accuracy.

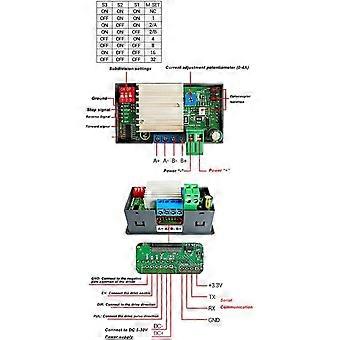

Easy integration and safe operation: builtin LCD display for status and configuration, TTL serial port for remote control, and input reverse connection protection to guard against wiring errors.

What it is and how it works

Main functions: auto mode for automatic sequencing, manual mode for handson adjustments, setting mode for configuration, and serial port control for external control and scripting.

Motor and driver compatibility: designed to control twophase stepper motors across 4, 5, 6, and 8 wires, and to drive drivers with similar interfaces.

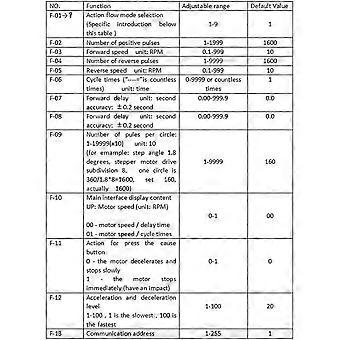

Pulse timing and positioning: the number of pulses per revolution is determined by the pilot subdivision and the step angle of the motor, allowing precise positioning based on the motor used.

Protection and control interfaces: features input reverse connection protection and a TTL serial port for remote communication.

Key features and specifications

LCD display: provides status visibility and configuration feedback for convenient setup and monitoring.

Acceleration and deceleration control: enables smooth start/stop and ramping to reduce mechanical load and improve repeatability.

TTL serial communication: enables straightforward remote control and integration with existing control systems.

Instruction set: optimized to streamline and simplify commonly used instructions, improving ease of programming and reliability.

Use scenarios

Scenario 1: Automated positioning on a compact CNC or automated mounting system where precise stepper control and serial integration are required.

Scenario 2: Laboratory automation or testing rigs that need repeatable motor indexing with remote control and configurable timing.

Scenario 3: Precision handling or inspection stations on a conveyor or positioning platform, where manual override and rapid setup changes are beneficial.

Notes

Pulses per revolution and overall performance depend on the chosen stepper motor angle and subdivision settings, in line with the pilot subdivision and motor specifications.

The device is designed to stay consistent with the original product brand, specifications, models, and functions without adding or omitting details.

-

Fruugo ID:

434893995-912419153

-

EAN:

6295761896588